Polyethylene Foam (Foam): what it is, properties and applications of protective foam

Polyethylene foam , commonly known as foam , is one of the most effective materials for protecting products during storage and transport . Although not always immediately recognizable, it is present in numerous packaging solutions: dividers, protective filler, scratch-resistant wrap, edge protection, and protection for delicate surfaces.

In this article you will understand exactly what it is , why it protects so well and in what applications it is used (from packaging to construction), as well as how to choose the right format for your needs.

What is polyethylene foam?

Polyethylene foam is a closed-cell foam . This means its structure is made up of microcells "sealed" together, like millions of tiny bubbles that don't communicate. What is achieved with this?

-

Moisture and water resistance (does not soak up like other foams).

-

Good shock and vibration damping .

-

Elasticity : it is compressed and tends to recover its shape.

-

Lightweight : protects without adding too much weight to the package.

These characteristics explain why polyethylene foam is used so much as a protective material in packaging and as insulation in certain technical solutions.

Key properties of polyethylene foam

1) Cushioning and scratch protection

The foam acts as a "cushion layer" that reduces impacts and, at the same time, prevents direct friction between pieces or surfaces, minimizing scratches (very useful in lacquered, painted products, glass, ceramic, aluminum, etc.).

2) Closed cell: moisture barrier

Because it has no open pores, it resists moisture better than open-cell foams. This is especially relevant in logistics, warehouses, and shipping where condensation or temperature fluctuations may occur.

3) Strength and flexibility

Depending on the thickness and density , it can behave as a flexible sheet (ideal for wrapping) or as a more rigid piece (ideal for separators and inserts).

4) Technical compatibilities (according to formulation)

There are variants with specific properties, for example:

-

Antistatic , for electronic components.

-

Flame retardants , more common in construction/insulation.

(These versions depend on additives and the type of product available).

What is polyethylene foam used for? Common applications

A) Protective packaging and shipping

It's their flagship app. It's used for:

-

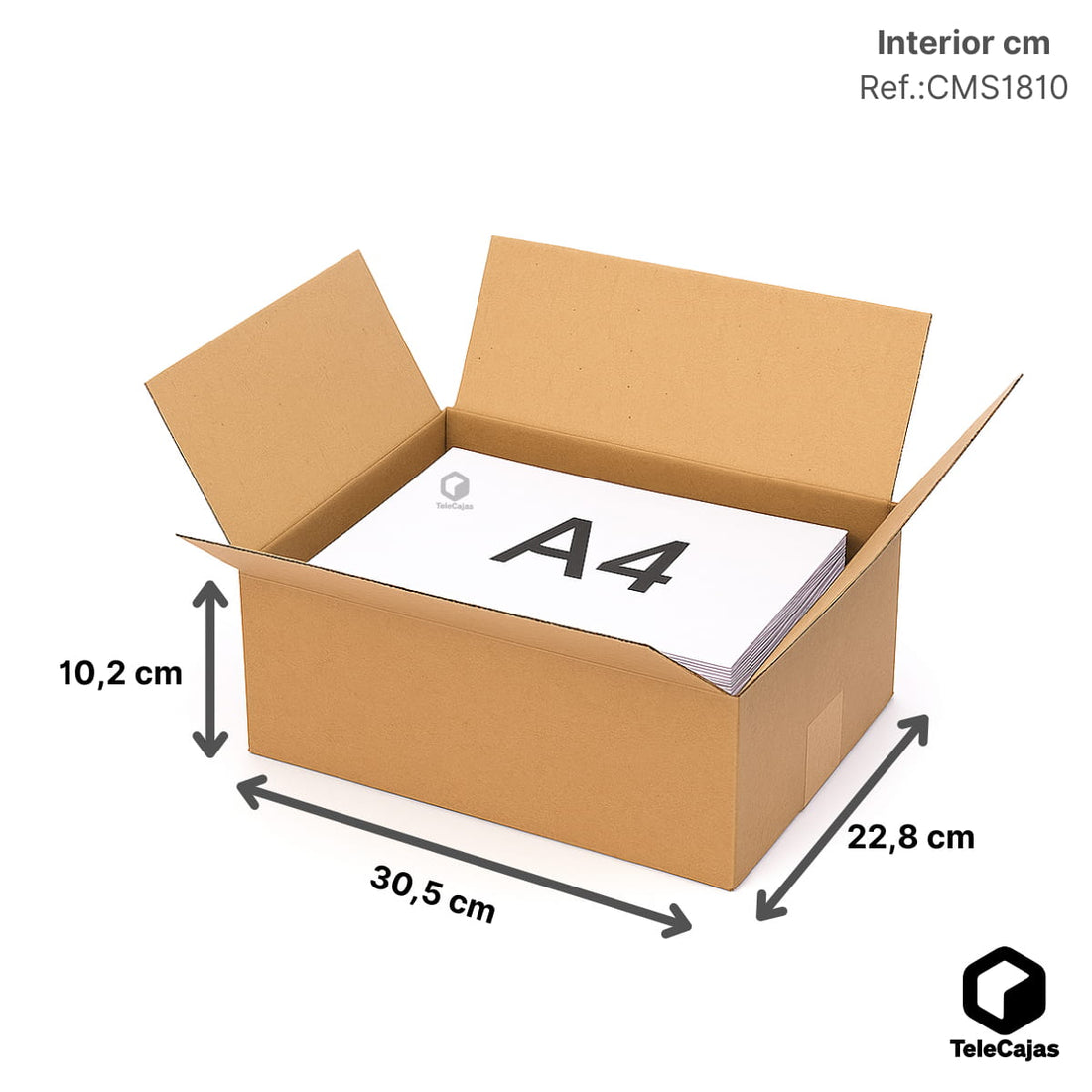

Wrapping products as an alternative or complement to bubble wrap.

-

Separate layers within boxes (between pieces, sheets, panels, frames, tiles, etc.).

-

Protect edges and corners on furniture and appliances.

-

Reduce vibration in transport (parcels, courier services, palletizing).

-

Avoid rubbing against delicate surfaces (glossy finishes, chrome, screens, methacrylate).

Practical tip: If your main goal is to avoid marks and scratches on surfaces, a thin foam is a very efficient solution.

B) Custom-made inserts and interior protection

In higher densities/thicknesses (or laminated), it can be cut to create:

-

Inserts for briefcases, cases and technical boxes.

-

Protective covers for parts with specific geometries.

C) Construction and insulation

Due to its resistance to moisture and its behavior as a barrier:

-

Thermal insulation and sealing solutions.

-

Separation between construction elements, joints, support and leveling (according to specification).

D) Automotive, sports and leisure

It is used in:

-

Acoustic insulation and interior protections.

-

Mats, technical floors, protections and flotation elements (due to their lightness and buoyancy).

How to choose the right foam (thickness, density and format)

When buying polyethylene foam, the following combination is usually preferred:

-

Thickness (mm):

-

2 mm : ideal for wrapping , sandwiching and protecting against chafing without adding bulk.

-

Greater thickness: more padding for impacts and greater separation between pieces.

-

Density:

Higher density usually means more resistance and better recovery (and also more "body" to protect). -

Format:

-

Roll : quick for preparing orders, cutting to size and wrapping products.

-

Plate / block : more useful for inserts or more structural protections.

Direct recommendation for packaging: 2mm foam roll

If you're looking for a practical solution to protect surfaces and minimize scratches during shipping (especially in e-commerce), a thin foam roll is the perfect solution.

You can link to it in the article with natural text geared towards purchase intent, for example:

Roll of 2 mm polyethylene foam (50 cm) for protective packaging

Typical uses of this format (2 mm):

-

Wrap pieces before putting them in the box.

-

Separate stacked products so they do not rub against each other.

-

Protect panels, frames, ceramics or painted surfaces.

-

Add a "clean" layer between product and more voluminous fillers.

Frequently Asked Questions (FAQ)

Does polyethylene foam help prevent scratches?

Yes. Especially in thin thicknesses, it is widely used as an anti-friction layer between delicate surfaces.

Does polyethylene foam protect against impacts?

It provides protection, but the level depends on the thickness and density . For heavy impacts, it is usually combined with other protective measures (padding, corner protectors, double-walled construction, etc.).

Is it water resistant?

Being closed-cell , it offers good resistance to moisture and does not soak up easily like other foams.

Can it be easily cut?

Yes. In roll or sheet form, it can be easily cut to adapt to different product sizes.

If you prepare shipments daily and want quick, lightweight, and effective protection against scratches, polyethylene foam is a safe bet. To get started with a very practical packaging format, here's the link to the product: 2 mm x 50 cm foam roll .